When we're choosing outdoor gear, we can't overlook the critical role that fabric selection plays in our backpack's performance. We've seen remarkable advancements in material technology that have transformed how we approach wilderness exploration and urban adventures alike. From ultralight Dyneema to reinforced ripstop nylon, today's fabric options offer an impressive balance of durability and weight reduction that wasn't possible just a few years ago. Yet with so many technical materials available, understanding which fabric will best serve our specific needs has become increasingly complex.

Understanding Modern Backpack Materials

Today's backpack materials offer an impressive array of options, from high-performance synthetics to eco-friendly natural fibers.

We've seen remarkable fabric innovations in recent years, with materials like nylon and polyester leading the charge in durability and weather resistance. These materials can be enhanced with PU coatings for waterproofing. While these synthetics excel in protecting our gear, they're not our only choices anymore.

For instance, ripstop fabric is particularly notable for its tear-resistant construction, which makes it a favorite among adventurers.

We're excited to explore sustainable alternatives that are changing the game. Hemp stands out as a fast-growing, biodegradable option that doesn't compromise on strength.

For those of us seeking eco-conscious choices, recycled materials like rPET and recycled nylon deliver the same reliable performance while giving plastic waste a second life.

When we need serious durability, ripstop and ballistic nylon provide unmatched protection for our adventures.

Let's not forget about specialized materials like Dyneema, which offers incredible strength without weighing us down.

Whether we're heading to school, work, or hitting the trails, understanding these material options helps us choose backpacks that match our lifestyle needs while considering our impact on the environment.

Benefits of Lightweight Fabric Choices

In light of growing demands for comfortable and practical backpacks, lightweight fabric choices now offer remarkable benefits that extend well beyond just reducing weight.

We're seeing exciting fabric innovations that combine durability with practical features, making our outdoor adventures and daily commutes more enjoyable.

Today's lightweight materials like nylon and polyester deliver impressive performance while supporting sustainability practices through options like recycled polyester (rPET).

We've found these materials excel in four key areas:

- Exceptional durability with high resistance to wear, tear, and UV damage

- Outstanding water resistance and quick-drying capabilities

- Easy maintenance and cleaning, perfect for active lifestyles

- Excellent shape retention and flexibility for varying loads

What's particularly exciting is how these fabrics adapt to different needs while maintaining their strength. The abrasion-resistant properties of these materials ensure they can withstand the toughest conditions without compromising performance.

Whether we're hiking through rough terrain or traversing busy city streets, modern lightweight fabrics offer the perfect balance of protection and comfort.

With improved thread counts and strategic stitching techniques, we're getting backpacks that last longer and perform better, all while keeping our environmental impact in mind.

Top Performing Synthetic Fabrics

Leading the charge in backpack innovation, synthetic fabrics have revolutionized how we build durable and lightweight packs for every adventure.

When we explore the top performers, nylon advantages stand out with its exceptional strength-to-weight ratio and remarkable resistance to wear and tear. We've seen how it excels in everything from daily commuter bags to rugged hiking packs.

Let's talk about polyester versatility, which offers incredible value for those seeking freedom in their gear choices. It's UV-resistant, maintains its shape beautifully, and won't break the bank. Many manufacturers now utilize recycled materials to create sustainable options.

We're particularly impressed by 600D polyester's outstanding durability and its availability in recycled options for environmentally conscious adventurers.

For those pushing the limits, specialized fabrics like Cordura and Dyneema deliver unmatched performance.

We've found that Ripstop variations, with their reinforced grid patterns, provide excellent tear resistance without adding unnecessary weight.

Whether you're scaling mountains or maneuvering through city streets, these advanced materials guarantee your gear keeps up with your lifestyle.

The right synthetic fabric choice means you'll spend less time worrying about your pack and more time exploring.

Weather Resistance and Protection

Beyond material strength, a backpack's ability to shield against nature's elements can make or break your outdoor experience. When we're selecting materials for rain protection, we look for fabrics that offer both waterproofing and breathability.

Modern synthetic materials like nylon and polyester, especially when treated with DWR or coated with TPU, give us excellent moisture management without weighing us down. Regular fabric maintenance helps preserve these protective qualities over time.

Let's explore the key features that make weather-resistant backpacks truly effective:

- Water-resistant coatings and membranes like Gore-Tex create a protective barrier while allowing sweat to escape.

- Ripstop nylon prevents tears and adds durability when we're pushing through rough terrain.

- Specialized fabrics like X-Pac and DCF provide superior protection against heavy downpours.

- Multiple layers of protection, including thermal barriers, keep our gear safe in extreme conditions.

We've found that the best weather resistance comes from combining these technologies. For instance, when we pair a breathable membrane with a DWR-treated outer layer, we get outstanding protection that maintains its effectiveness over time. This approach also ensures compliance with the IPX Rating System, guaranteeing our gear stays dry while we stay comfortable on the trail.

This combination guarantees our gear stays dry while we stay comfortable on the trail.

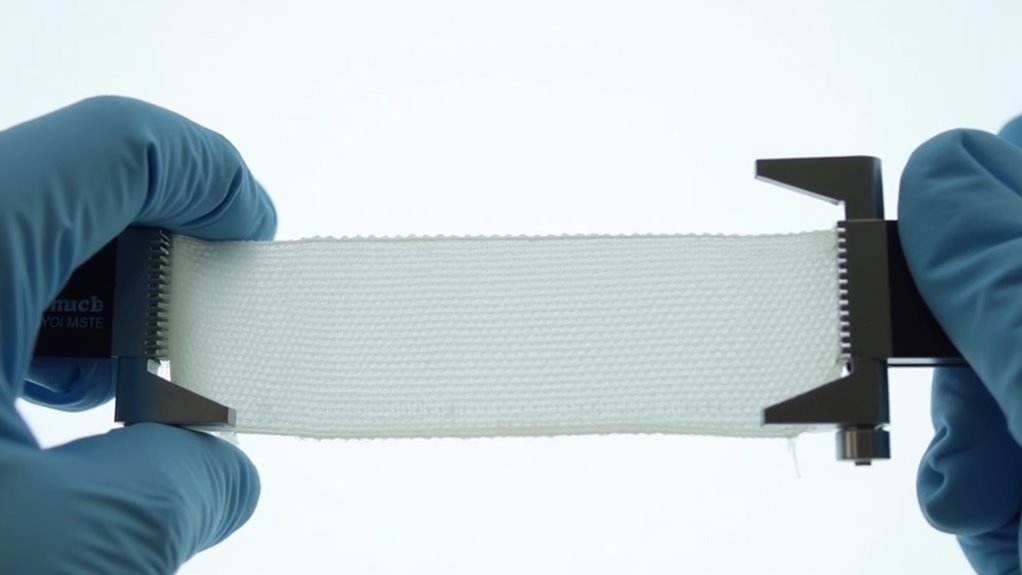

Durability Testing and Standards

To guarantee backpacks meet rigorous quality standards, manufacturers employ an extensive suite of durability tests that evaluate material strength and longevity.

Laboratory analysis through controlled environments helps isolate specific performance factors that might be missed during field testing, such as assessing the pack's ability to withstand various weather conditions.

We'll walk you through the primary fabric assessment methods that ascertain your pack won't let you down when you need it most.

The testing methods start with bursting strength tests, where technicians push a metal ball through the fabric until it breaks – this tells us how well your pack will hold up under pressure.

We then look at tear strength, which shows how resistant the material is to rips by measuring the force needed to extend an existing tear.

For everyday wear and tear, we've got the Martindale and Wyzenbeek tests, where we rub the fabric thousands of times to check its abrasion resistance.

Don't forget about flex endurance – we use special machines called Flexometers to bend and flex the material repeatedly, just like you'd do with your backpack.

These tests help us understand how the fabric will perform in real-world conditions, so you can trust your gear when you're out exploring the world. Additionally, they ensure that materials like nylon are durable and weather-resistant.

Cost Versus Performance Analysis

Backpack manufacturers face critical decisions when balancing cost against performance in today's ultralight gear market.

When we look at performance metrics across different materials, we find that premium fabrics like Dyneema deliver exceptional strength but come at a higher price point. Our cost analysis shows that X-Pac offers an attractive middle ground, providing significant weight savings while keeping costs manageable. This is particularly important for achieving a low base weight, which is essential for long treks.

The waterproof film layer in X-Pac provides protection up to 200 PSI, making it exceptionally resistant to harsh weather conditions.

Let's break down what you're getting for your money with these advanced materials:

- Dyneema packs typically cost twice as much but save about 100g per 30-liter capacity.

- X-Pac delivers excellent durability with 15x better abrasion resistance than traditional materials.

- Ultra fabric blends offer an ideal balance of weight and longevity.

- Custom gear options become more accessible with X-Pac's lower price point, allowing backpackers to invest in multi-use items that serve several purposes.

We've found that investing in these robust lightweight materials often pays off in the long run.

While the initial cost might be higher, the extended lifespan and improved performance make them worth considering. For those seeking freedom on the trail, the weight savings and durability of these modern fabrics can transform your hiking experience by reducing strain on the body and increasing hiking efficiency.

Frequently Asked Questions

Can I Repair Tears in Lightweight Backpack Fabric at Home?

We can repair backpack tears at home using simple patching techniques and fabric adhesives. Let's clean the area, apply reinforced tape, sew on patches, and seal the repair properly.

How Often Should I Clean My Lightweight Backpack to Maintain Durability?

We'll spot clean your lightweight backpack weekly and deep clean monthly. For daily adventures or weekend wanderings, let's maintain durability through gentle cleaning techniques and proper drying routines.

Do Lightweight Backpack Fabrics Lose Their Water Resistance Over Time?

Yes, we'll see our lightweight backpack's water resistance fade with time. It's natural as coatings wear off, but we can maintain fabric longevity through regular waterproofing treatments and proper care.

Which Thread Types Work Best for Reinforcing Lightweight Backpack Seams?

We've found bonded nylon thread offers ideal seam reinforcement and thread durability. It's strong, flexible, and won't degrade like polyester. PTFE-coated threads add extra water resistance for critical seams.

Are Eco-Friendly Lightweight Backpack Materials as Durable as Synthetic Ones?

When testing hemp backpacks in rough terrain, we've found eco-friendly durability matches synthetic comparisons in most cases, though synthetics excel in extreme conditions where specialized performance is needed.

Conclusion

Like a feather in the breeze, today's lightweight backpack fabrics offer us the perfect balance of strength and portability. We've seen how modern materials transform our outdoor experiences, making every step lighter while keeping our gear protected. By choosing robust yet lightweight fabrics, we're investing in comfort, durability, and peak performance. It's clear that these innovative materials aren't just an option – they're essential for maximizing our adventures.